Changzhou Original Chemical Co., Ltd

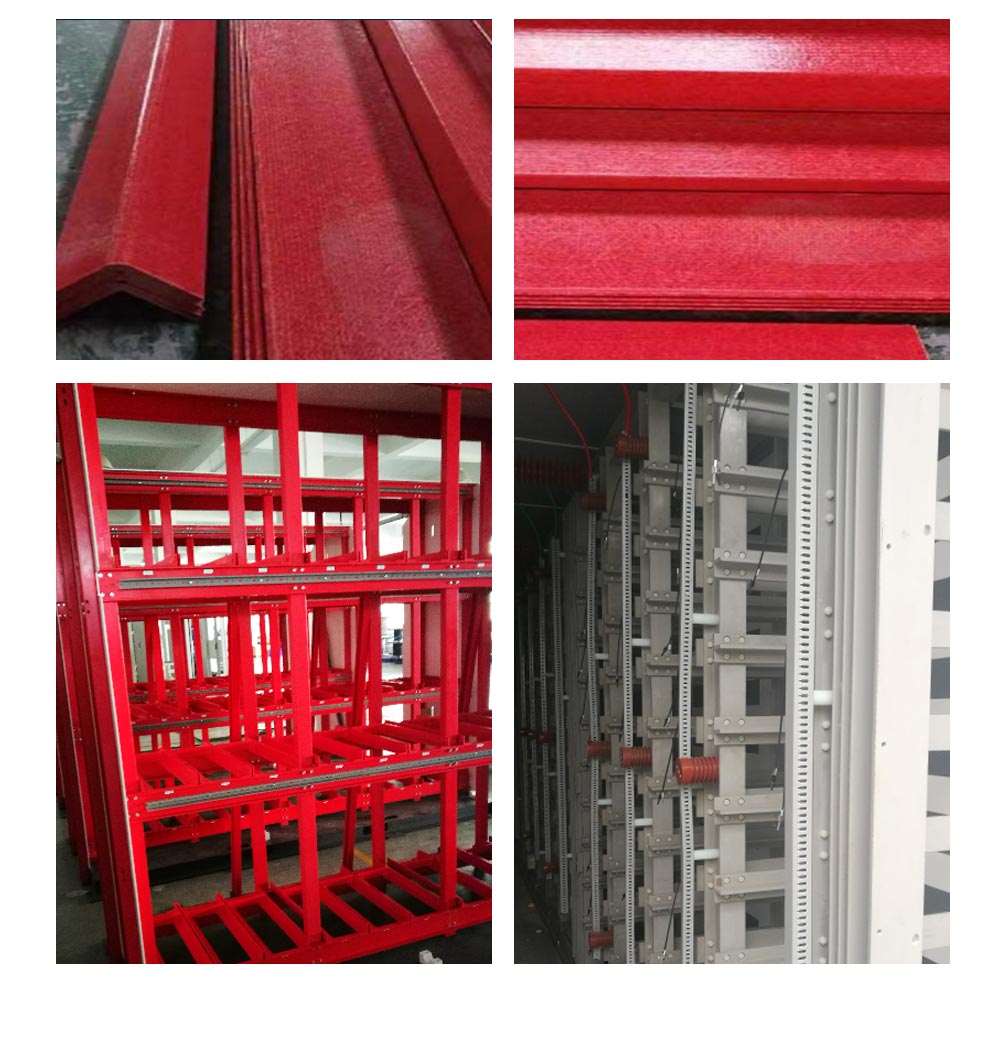

GRP composite high performance profiles

High Performance FRP structural section is a typical composite structural member. Because of its high bending stiffness and strength, it has better bearing capacity in structural engineering, the low density of the product, compared with the traditional metal materials, fiber-reinforced composites have lighter weight, thus reducing the overall structure of the weight, processing performance and other excellent characteristics, widely used in the electrical industry insulation structure parts, beam, cable bridge, rail transit support insulation, aviation, aerospace, automotive, construction, sports equipment and other fields are now widely used.

The pultruded profiles of fiber reinforced composites also have good corrosion resistance. Fiber-reinforced composites are less susceptible to water and chemical attack than metallic materials.

From High Performance Composite FRP structural profiles, using unsaturated polyester resin, epoxy resin, polyurethane resin, Phenol formaldehyde resin, etc. as the matrix, glass fiber, quartz fiber, glass felt, glass cloth, basalt cloth, electronic cloth, carbon fiber and so on are reinforcing materials, the GRP profiles of different sizes are formed by Pultrusion and Press moulding.

The FRP profiles formed by pultrusion process are suitable for producing FRP profiles with the same cross-section shape. In the PULTRUSION process, the uniformity and continuity of fiber reinforcement are very important, to ensure the stability of the final product size and performance.

The profile with special-shaped structure has good design freedom and is suitable for molding process. The fiber reinforcements can be arranged directionally to meet different engineering requirements.

1.Purpose description

Temperature: -30-100 ° C

Color: white, red, gray, yellow, etc.

Application Fields | Purpose description |

Solar energy, wind energy storage switchgear | SVG Energy Storage Cabinet, no attack compensation: unit cabinet insulation parts; all kinds of profiles: column, cross, beam, safety bar, line groove, etc. |

Switchgear equipment | The front end, the back end, the upper end, the low end, the phase separation plate support matches the skeleton and the fixed function and so on |

Cable support frame | All kinds of partition board, lining board, arc-extinguishing cover, arc-extinguishing cylinder, arc-extinguishing piece, arc-isolating board, Wiring Board, insulation between each other, bottom-end partition board, switch and transformer structural support parts, cable laying framework components, etc. |

2.Classification

Classify models by performance

Model | Applications and features |

Pultrusion profile | It has good electrical performance at high humidity, good mechanical performance at high temperature, heat resistance grade 'F' electrical temperature index greater than 130 ° C, mechanical temperature index greater than 155 ° C, low smoke, flame retardancy, etc. |

Press moulding profile | According to the product structure, open-die do model structural parts, product electrical performance, mechanical performance, fire performance, heat resistance grade“F” class; electrical temperature index greater than 130 ° C, mechanical temperature index greater than 155 ° C, low smoke, flame retardant, etc. |

Remarks | |

3.Technical requirements

3.1 appearance

The surface is flat and smooth, with traces of fibers and no bubbles or cracks allowed

3.2 specifications and sizes

3.2.1 specification table

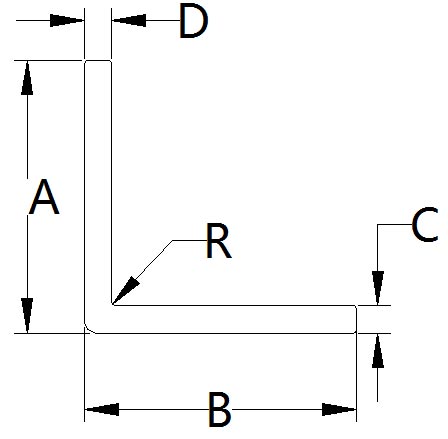

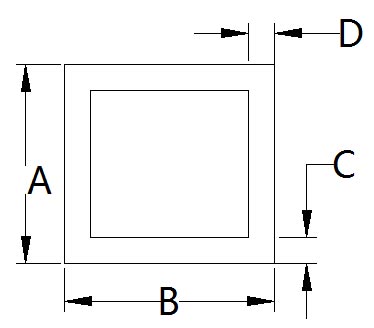

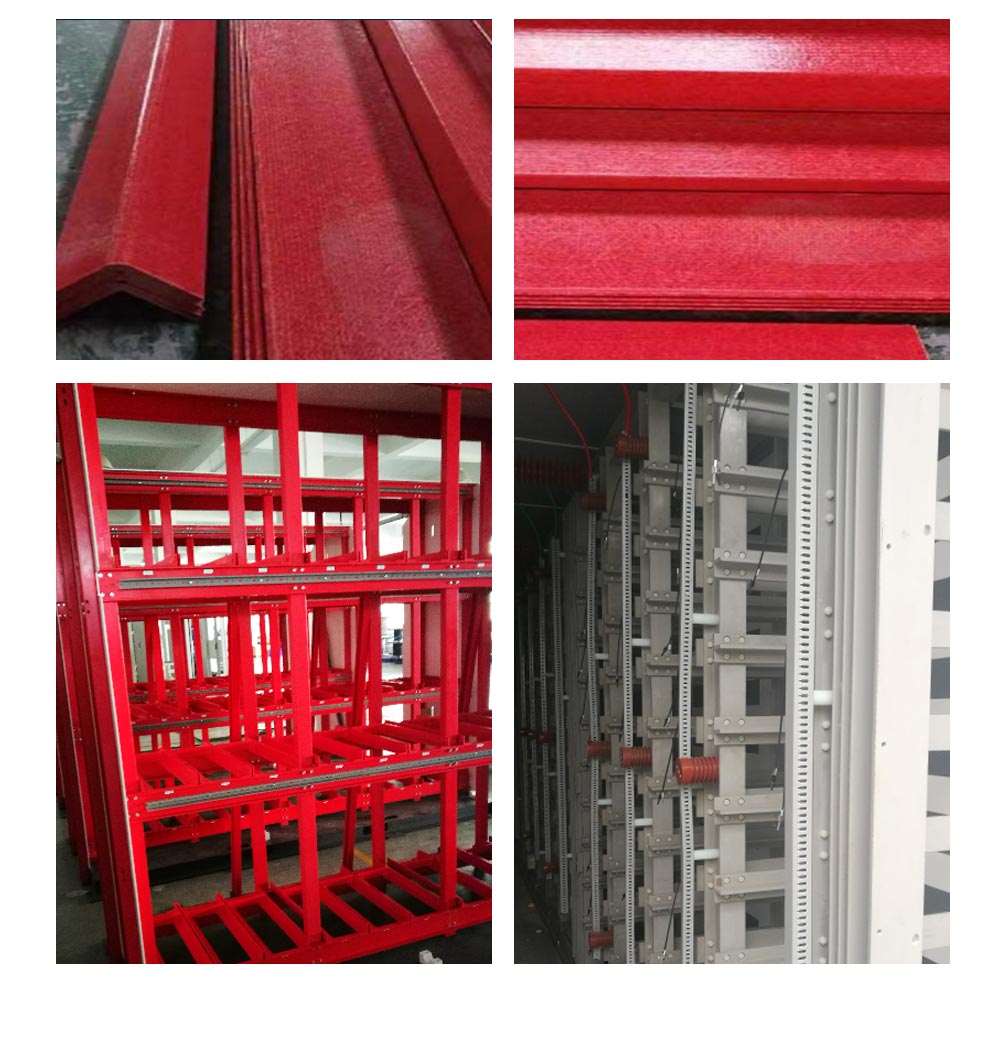

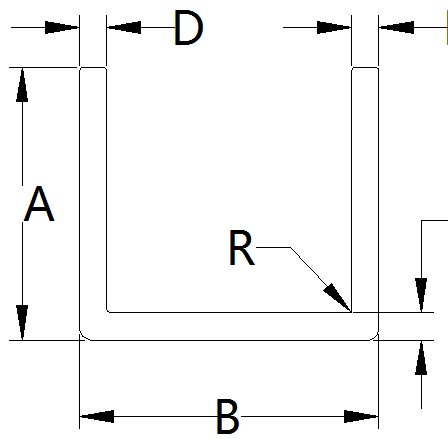

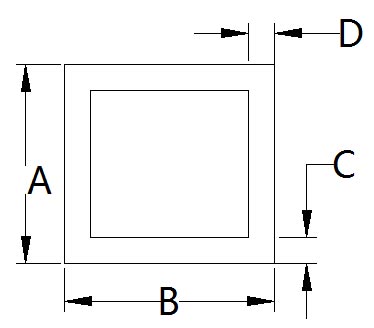

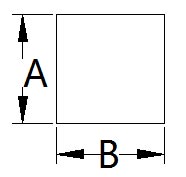

NO | Shape | Size(mm) | Icon |

length | A | B | C | D | R |  |

1 | Pultrusion

'L'

| requested | 50 | 50 | 5 | 5 | 2 |

2 | requested | 50 | 50 | 6 | 6 | 2 |

3 | requested | 40 | 40 | 5 | 5 | 2 |

4 | requested | 130 | 35 | 5 | 5 | 2 |

5 | requested | 150 | 35 | 6 | 6 | 2 |

6 | requested | 65 | 65 | 8 | 8 | 2 |

7 | Press moulding

'L'

| 2500 | 76 | 44 | 9 | 9 | 2 |

8 | 2600 | 40 | 40 | 5 | 5 | 2 |

9 | 1000 | 50 | 50 | 6 | 6 | 3 |

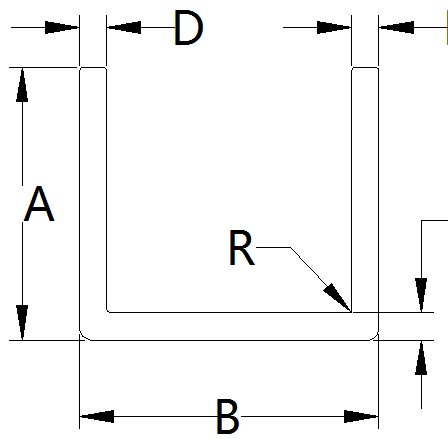

1 | Press moulding 'U' | 2600 | 35 | 60 | 7 | 7 | 2 |  |

2 | 2600 | 30 | 100 | 6.5 | 6.5 | 2 |

3 | 2500 | 50 | 100 | 8 | 8 | 2 |

4 | 2500 | 30 | 70 | 6 | 6 | 2 |

5 | 2000 | 22 | 40 | 5 | 5 | 2 |

6 | 1500 | 45 | 127 | 45 | 7 | 2 |

7 | Pultrusion

'U' | requested | 45 | 120 | 8 | 8 | 2 |

8 | requested | 45 | 127 | 10 | 10 | 2 |

9 | requested | 45 | 160 | 45 | 9 | 2 |

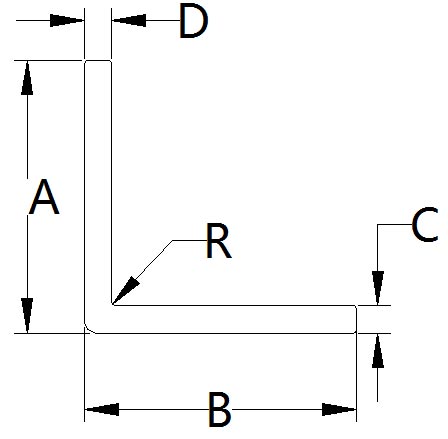

NO | Shape | Size(mm) | Icon |

length | A | B | C | D | R |  |

1 | Pultrusion

'' | requested | 70 | 30 | 8 | 8 | 2 |

2 | requested | 60 | 30 | 5 | 5 | 2 |

3 | requested | 80 | 80 | 6 | 6 | 2 |

4 | requested | 100 | 100 | 3 | 3 | 2 |

5 | Pultrusion rod

'' | requested | 25 | 25 | - | - | 2 |  |

Note:

1. Tolerance is ISO 2768 'c' and 'v' .

other specifications of non-standard products size and thickness tolerances can be negotiated by both sides, according to the requirements of processing.

3.3 physical and mechanical properties

| NO | Items | Unit | Pultrusion types | Press moulding types | Test method |

1 | Appearance | _ | The surface is smooth, flat, no crack, with fiber lines (visual inspection) |

2 | Density | g/cm3 | 1.9~1.95 | 1.75-1.9 | ISO 1183-1:2004(A)

GB/T 1033.1-2008 |

3 | Water absorption | % | ≤0.3 | ≤0.25 | ISO 62:2008; GB/T 1033-2008 |

4 | Longitudinal bending strength | Mpa | ≥300 | ≥200 | ISO178:2001

GB/T 9341-2000 |

5 | Longitudinal bending modulus | Gpa | ≥15 | ≥10 |

6 | Vertical impact strength (no notch) | KJ/m2 | ≥120 | ≥80.0 | ISO179-1:2000

GB/T 1043.1-2008 |

7 | Longitudinal compression strength | Mpa | ≥260 | ≥160 | ISO 604:2002 |

8 | Longitudinal tensile strength | Mpa | ≥150 | ≥90 | ISO180 IDT

GB/T 1634.2-2004 |

9 | H.D.T(Tff1.8) | º C | ≥150 | ≥150 | ISO 75-2:2003

GB/T 1634.2-2004 |

10 | Barcol hardness | - | ≥55 | ≥45 | GB/T 3854-2005 |

11 | Fiber content | % | ≥65 | ≥40 | ISO1167 |

Note: 1.Because of the difference of products, the user can confirm the performance according to the needs;

2. the product performance is based on the referenced standards, customer measured values will vary according to product thickness, workpiece structure, etc. . |

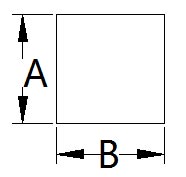

Product Pictures